Prototype Aluminum Casting: Innovative Techniques and Solutions

Prototype aluminum casting creates test parts using aluminum metal poured into molds. This process helps engineers test designs before making full production runs. It saves time and money by catching problems early in the development stage.

Today’s manufacturers are under intense pressure to accelerate product development. Innovative solutions are key. Bain & Company reports that three out of four advanced manufacturing companies prioritize adopting technologies like artificial intelligence (AI) to increase productivity and boost performance.

At Griffin Industries, we see how the right casting approach changes everything. Companies that once waited months for prototypes now get them in days. This speed advantage can help them stay ahead of competitors and respond quickly to market demands.

Keep reading below to learn more.

What Is Prototype Casting?

Prototype casting makes small batches of parts for testing and design work. Unlike mass production, it focuses on speed and accuracy. Engineers can make changes without spending big money on new tools.

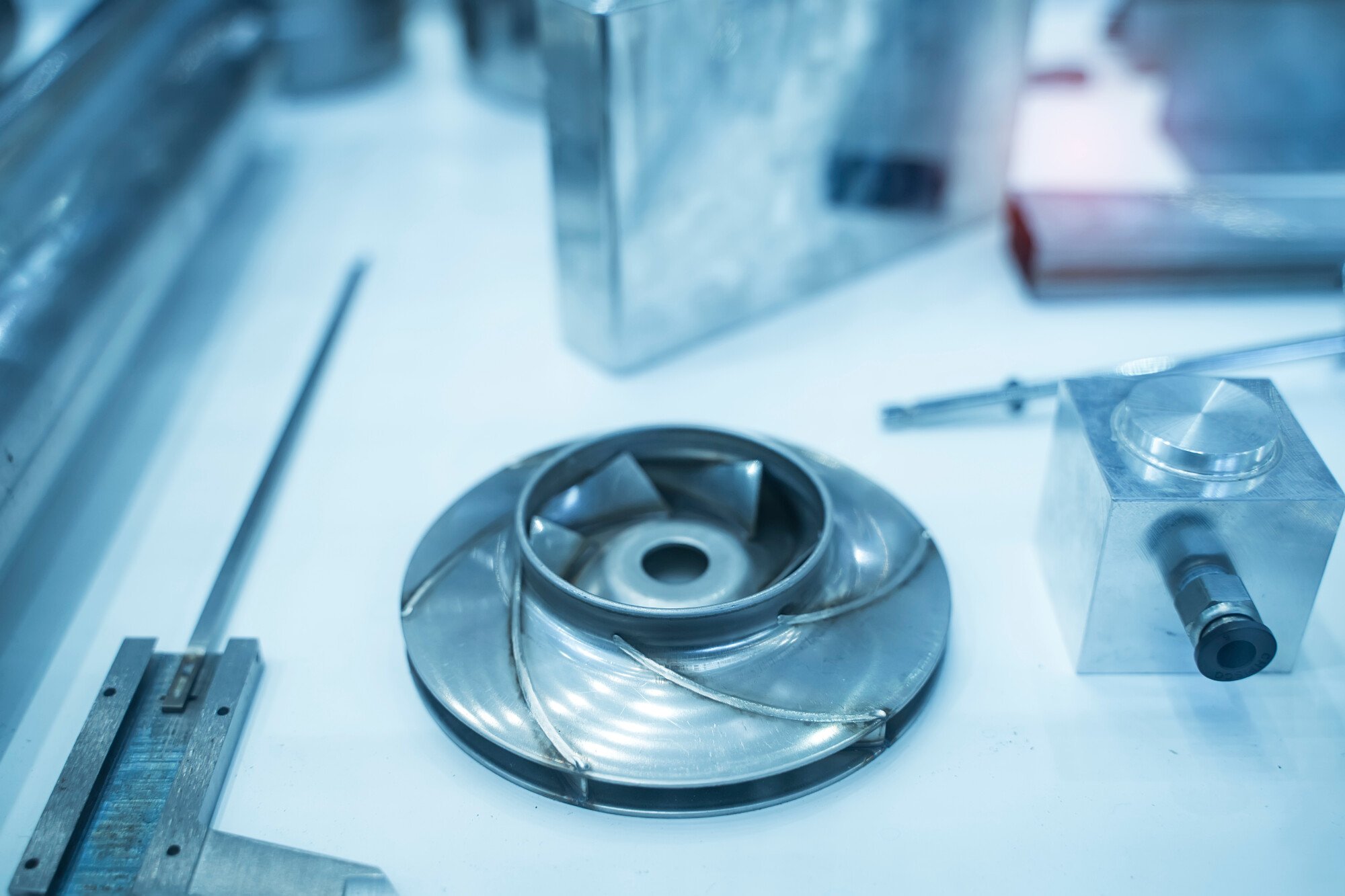

The process starts with creating a pattern that matches your desired part. Then you pour hot aluminum into a mold made from that pattern. The result is a working prototype that acts like the final product. This method lets teams spot problems early.

They can test the part, find issues, and fix them before spending money on production tooling. Modern prototype casting offers several smart approaches:

- Rapid tooling that cuts weeks down to days

- 3D printed patterns that skip traditional pattern making

- Mixed techniques that combine the best of different methods

- Computer tools that predict problems before casting begins

The best part about prototype casting is how fast you can improve designs. Make a part, test it, change what doesn’t work, and create a better version within days instead of months.

What Technology Allows Designers to Prototype New Products Quickly and Cheaply?

Digital tools have transformed how designers approach prototype aluminum casting. Computer design software now connects directly with casting programs. This allows engineers to see how aluminum will flow through molds before pouring any metal.

Some key technologies revolutionizing prototype development include:

3D Printing Integration

3D printing has revolutionized rapid prototyping. Designers can now print patterns, cores, and even whole molds. This dramatically cuts the time and cost of traditional tooling methods. The technology creates complex internal shapes that would be impossible or too expensive with old methods.

Smart Systems and AI

Smart computer systems now use artificial intelligence to make casting better. These programs adjust temperatures, cooling speeds, and mold designs based on real-time information. The result is higher-quality prototypes with fewer do-overs.

Virtual Reality Applications

Virtual reality and augmented reality are finding new uses in casting work. Engineers can see cast parts in 3D space, spot assembly problems, and work with teammates anywhere in the world.

Understanding Aluminum Prototyping: From Concept to Reality

The journey from design idea to finished aluminum prototype involves several key steps. Each step needs careful attention and technical skill. Understanding these prototype casting processes helps manufacturers make smart decisions.

The process begins with design review and material choice. Engineers look at the intended use, required strength, and manufacturing limits. They use this information to pick the best aluminum type and casting method. This first step often determines if the whole project succeeds.

Pattern and tooling development come next. Traditional methods now get help from technology adoption. Modern foundries can make casting patterns using:

- 3D printing

- Computer-controlled machines

- Mixed approaches that combine different aluminum casting techniques

Mold preparation and casting require specialized knowledge to ensure consistent quality. Aspects like pouring temperature, mold heating, and cooling speed all affect the final prototype’s properties. Advanced monitoring systems help control these critical factors.

After casting, operations like heat treatment, machining, and surface finishing turn rough castings into precise prototypes. These finishing steps often decide whether a prototype represents the intended production part.

Advance Your Projects with Professional Prototype Aluminum Casting

The future of prototype aluminum casting lies in combining digital technologies with traditional foundry expertise. Companies that embrace these innovative casting methods will be better positioned to meet market demands and expedite their product development.

At Griffin Industries, we know that prototype aluminum casting success depends on matching engineering needs with foundry skills. Our team works closely with clients to improve designs for manufacturing while keeping the functional requirements that make prototypes valuable for testing.

Ready to streamline your prototyping process? Request a quote today and see how our high-efficiency aluminum casting for prototypes will transform your product development approach.

Frequently Asked Questions

What makes aluminum casting different from other metal casting processes?

Aluminum casting has unique benefits, including lower melting temperatures and excellent rust resistance. The metal flows well when hot, allowing for detailed parts. It also cools quickly, enabling faster production cycles compared to iron or steel casting.

Aluminum’s lightweight nature makes it ideal for applications where weight reduction is critical, such as automotive and aerospace components.

How long does prototype aluminum casting typically take?

The prototyping timeline depends on part complexity and the chosen method. Modern rapid aluminum casting techniques can deliver simple prototypes within 3-5 days. More complex parts needing investment casting or extensive machining may take 2-3 weeks. Digital pattern creation and 3D printing have cut traditional lead times significantly.

What industries benefit most from prototype aluminum casting?

Automotive, aerospace, defense, and construction industries rely on aluminum prototypes for part validation. These sectors need parts that accurately represent production characteristics for testing performance, fit, and function before investing in expensive production tooling.

Can prototype castings match production part quality?

Yes, when done properly, prototype aluminum castings can closely match production part strength and dimensional accuracy.

Smart alloy selection, controlled cooling processes, and professional finishing techniques ensure prototypes provide reliable testing data for design validation.

What are the cost advantages of aluminum prototype casting?

Aluminum prototype casting offers significant cost savings compared to machining parts from solid blocks. The process reduces material waste and eliminates expensive tooling investments for early-stage testing. Companies can make necessary design changes before committing to high-volume production tooling, helping them avoid costly redesigns later in the development process.